The Department of Mechanical Engineering

The Department of Mechanical Engineering at Seth Vishambhar Nath Institute of Engineering and Technology Barabanki was established in 2008. The department offer 4 year B. Tech. Program in Mechanical Engineering is recognized by AKTU (AICTE). The main goal of the department was to fulfill the need of an undergraduate engineer to have proper knowledge and to be practically aware of various mechanical machines. We also help our students in mini projects and industrial training for their advancement in mechanical field and to have a better idea of theory at practical level. Our department objective is to generate a mechanical engineer who is a complete package of knowledge, ethics and practical ideas for a better future of our society at global level.

Newsletter

Achievements

Departmental Society

Institute–Industry Interaction

Vision of the Department:

To provide eminence education in Mechanical Engineering, enhancing the academic aptitude, innovative, immediate contributors to their profession and successful in advanced studies to enable them for meeting the needs of society for today and time ahead.

Mission of the Department:

M-1: Imparting quality education equipped with the latest techniques to make graduates competitive in all-inclusive.

M-2: To collaborate in research and development with industries for achieving excellence in research.

M-3: To develop quality in graduates by providing a favorable academic environment, governance, and ethical guidelines for a productive career in the technical field.

M-4: Providing trained and experienced faculties focused to impart knowledge of Mechanical Engineering and making the graduate’s future ready.

Program Educational Objectives

(PEOs)

PEO-1: To apply fundamental technical knowledge and skills to find workable solutions to technological challenges and problems in the areas of mechanical engineering.

PEO-2: To impart knowledge equipped with the latest software and techniques.

PEO-3: To impart high-quality multidisciplinary technical knowledge to graduates.

PEO-4: To enhance the professional career of graduates through continual learning with good technical competency and team spirit.

PEO-5: To design and develop engineering system components with a sense of ethics and professionalism for the benefit of the industry along with society.

Program Outcomes (POs)

(Engineering Graduates will be able to)

PO-1 Engineering Knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

PO-2 Problem analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

PO-3 Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

PO-4 Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data and synthesis of the information to provide valid conclusions.

PO-5 Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations.

PO-6 The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

PO-7 Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

PO-8 Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

PO-9 Individual and team work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

PO-10 Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

PO-11 Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

PO-12. Life-long learning: Recognize the need for and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Program-Specific Outcomes

(PSOs)

After the successful completion of my B.Tech. Program in “Mechanical Engineering” the graduate will have

PSO-1 An ability to identify, analyze and solve Mechanical engineering problems and also for the advancement of society and self.

PSO-2 An ability to use the accomplished principles of mechanical engineering to evaluate and create a new mechanical system or processes for the nation, and advancement of society.

PSO-3 An ability to adopt the latest software for designing/modeling, analyzing, and computing new products and solving real-life problems.

Message from HoD’s Desk

Mr. Shashi Kant Jaiswal

(Head of Department)

Area of Interest: Strength of Material, Theory of Machine, Engineering Mechanics

Welcome to the Mechanical Engineering Department (MED). This department offers the program of Bachelor of Technology (B.Tech.) in “Mechanical Engineering” The aim of the department is to provide well optimal teaching, learning methodology for overall growth of the students and acts as a Core of Excellence in Mechanical Engineering.

The focus of the Department is to provide better educational environment and enhancing practical knowledge to fulfill the industrial needs, and also encourage them to build their career for higher studies.

Our Department provides multiple facilities to the students in enhancing their practical skills which brings then exposure to many laboratories which are as follows Fluid Mechanics & Machines, Solid Mechanics, Strength of Materials, Dynamics and Control, Refrigeration and Air Conditioning, Heat Transfer…etc.

Ultimate importance is given to instruct better quality education and moral values. A beneficial ambiance is created to empower the students to relish the maximum benefits out of the available modern equipments.

With Best Wishes

Department of Mechanical Engineering.

Mechanical Engineering Faculties

Mr. Gaurav Sachan

(Assistant Professor)

Area of Interest: Thermal Engineering, Heat & Mass Transfer, Plant Engineering, Thermodynamics.

Mr. Ajai Kumar Verma

(Associate Professor)

Area of Interest: Heat &Mass transfer, I C Engine, Fluid Mechanics & Fluid Machines.

Mr. Malkhan Tiwari

(Assistant Professor)

Area of Interest: Fundaments of Mechanical Engineering, Thermodynamics, Industrial Engineering.

Mr. VINCY SATYAM

(Assistant Professor)

Area of Interest: Fluid Mechanics, Industrial Engineering, Renewable Energy Resources, Hydraulic and Pneumatics, Non Destructive Testing.

Mr. Parmod Kumar Yadav

(Assistant Professor)

Area of Interest: Manufacturing process, Machine design, Nondestructive testing.

Mr. Vikash Dwivedi

(Assistant Professor)

Area of Interest: Machine Design, CAD/CAM, Production.

Mr. Pankaj Verma

(Assistant Professor)

Area of Interest: Theory of Machines, I.C Engines.

Mr. Rohit Maurya

(Assistant Professor)

Area of Interest: Total Quality Management, Engineering Material, Robotics and Automation, Machine Design.

Mr. Arvind Kumar

(Assistant Professor)

Area of Interest: Thermodynamics, Engineering Mechanics, I C Engine.

Mr. Rameshwar Pandey

(Assistant Professor)

Area of Interest: Manufacturing Science, Tool Engineering, Welding Technology.

Mr. Mohammad Sazid Ali

(Assistant Professor)

Area of Interest: Engineering, Machine Design, Engineering Drawing, Constitution of India, Energy Science and Engineering.

Mr. Awanish Kumar

(Assistant Professor)

Area of Interest: Energy Technology and Management, Manufacturing Science, Strength of Material.

Mr. Indrakesh Kumar Yadav

(Assistant Professor)

Area of Interest: Fluid Mechanics, Theory of Machine, Material Science, Thermal Engineering, Production Technology.

Dr. Atiqur Rehman

(Associate Professor)

Area of Interest: Fluid Mechanics & Fluid Machines, Thermodynamics, IC Engine, Automobile Engineering, Computational Fluid Dynamics (CFD), Total Quality Management (TQM)

Syllabus

Syllabus

B. Tech. 2nd Year

B. Tech. 3rd Year

B. Tech. 4th Year

Newsletter

Achievements

Departmental Society

Institute–Industry Interaction

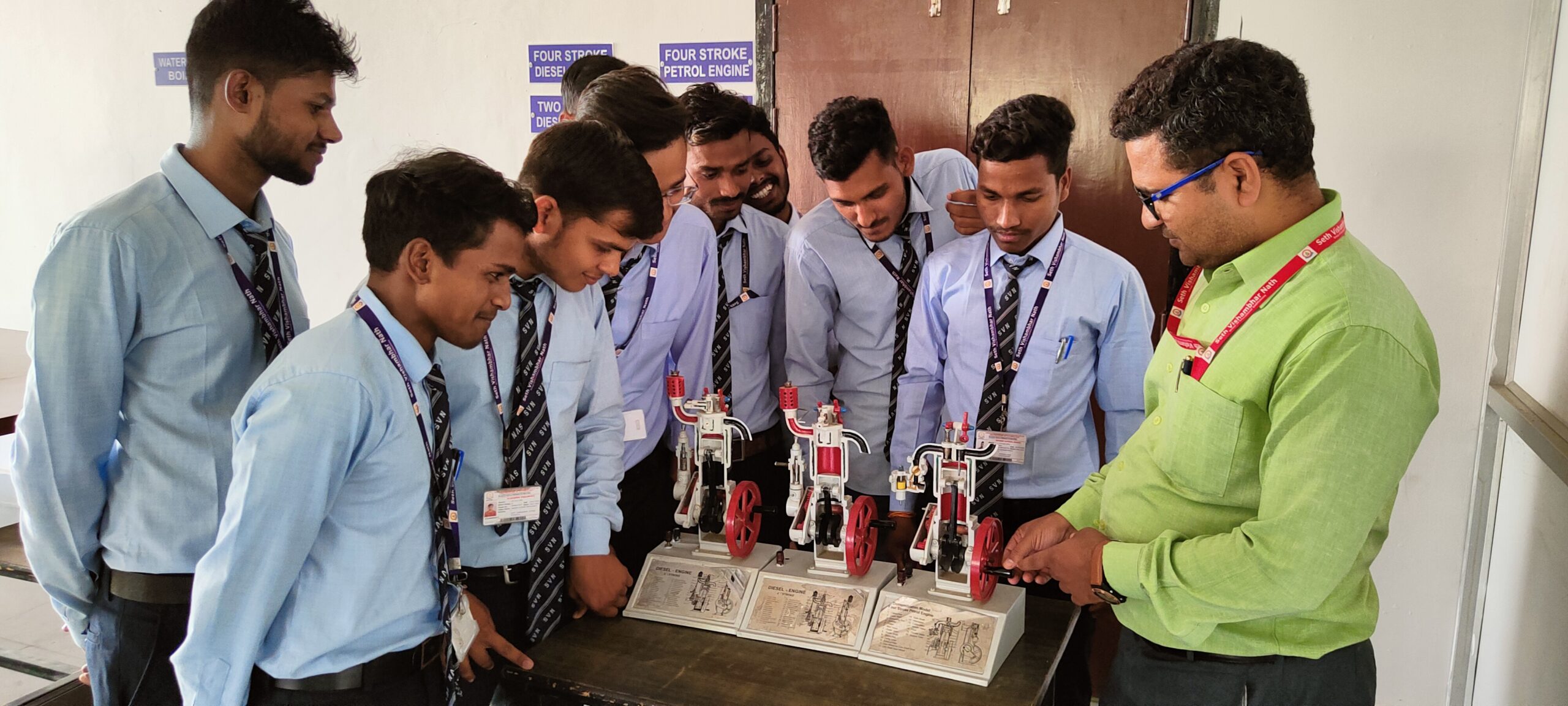

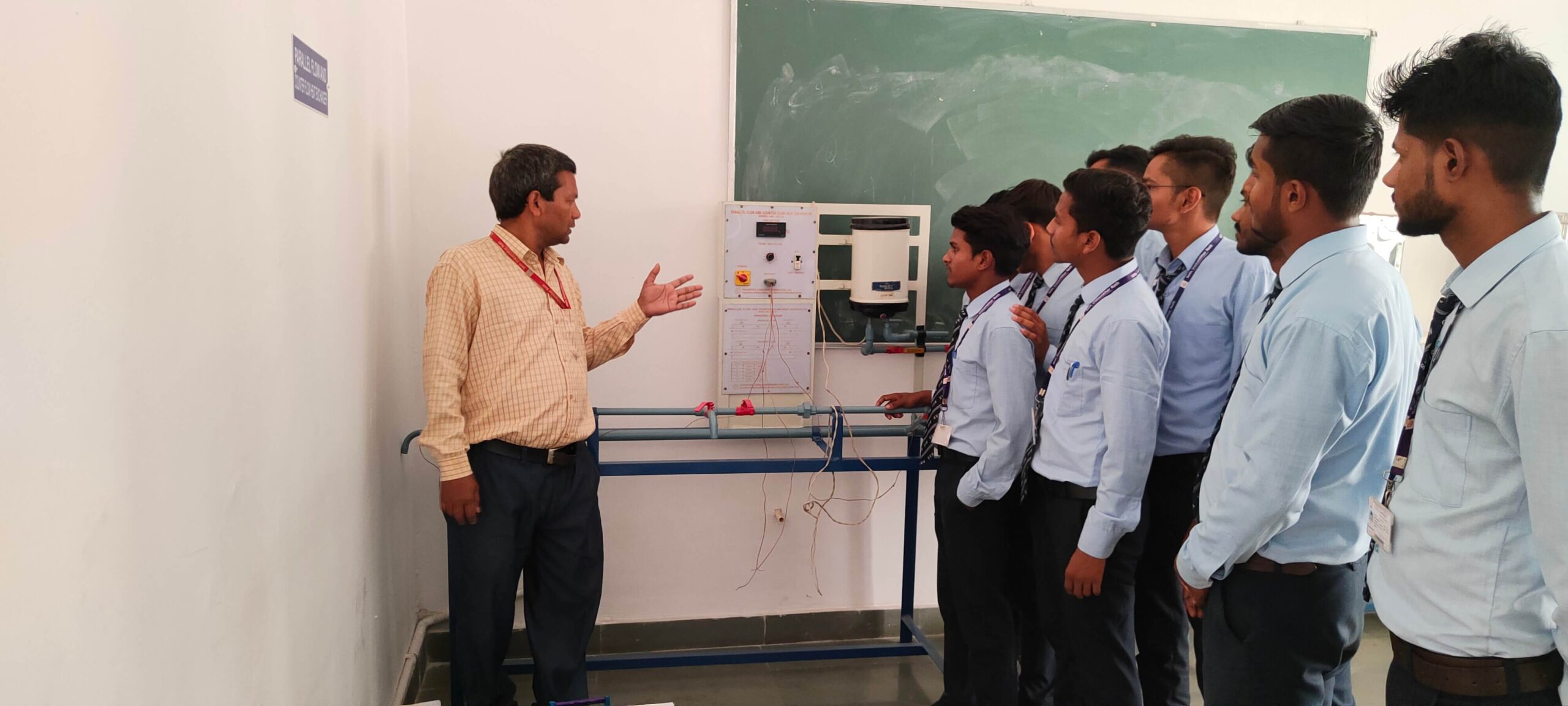

Mechanical Engineering Labs

In the Mechanical Engineering Department, various labs are provided with updated specification of apparatus and instruments for improvement and practical understanding to enhance the concepts of theoretical and practical knowledge.

The Mechanical Engineering labs provide an opportunity to learn the technology through equipped machines/ instruments labs with Lathe machines, Universal Testing machine, Fluid mechanics/ Fluid machinery, Refrigeration & Air conditioning, Heat and Mass transfer apparatus, ….etc.

The purpose of laboratories is to provide the practical application of the studied curriculum, so they can improve the concept and apply their creative imaginations and professional skills with combination of both theory and practical knowledge in different situations. Following are the major laboratories:

Fluid Mechanics Lab

The Fluid Mechanics laboratory is designed according to the curriculum to examine the properties of fluids (Liquid, Gas & Air) and to conduct experiments, investigating the fundamentals of fluid statics as well as kinematics and kinetics of fluid flow and involving incompressible flow, to enhance the hands-on experience of students.

The fluid mechanics lab consists of various experiments designed to help students understand the fundamental concepts of fluid mechanics. The experiments include: Reynolds Experiment, Bernoulli’s Theorem Experiment, Orifice Meter Experiment, Pitot Tube Experiment.

Through the experiments conducted in the lab, students gain practical knowledge in fluid mechanics and learn how to apply theoretical concepts to real-world scenarios.

Material Testing Lab

Department of Mechanical Engineering offers a well-equipped lab, which provides ideas on the practical knowledge for testing several properties of material like hardenability, surface roughness, ductility, malleability, .etc.

In this lab, students learn about UTM for compressive, shearing, bending, tensile tests, Izod-Charpy impact testing machine, Brinell testing machine, Vickers testing machine, furnace, polishing machine and metallurgical microscope, Pin and Disc type wear testing machine etc.

Material testing lab, offers comprehensive testing services to help determine the properties and characteristics of various materials. Our lab is equipped with state-of-the-art testing equipment and staffed with experienced professionals to provide accurate and reliable results.

Computer Aided Machine Drawing-I Lab

The CAD lab is equipped with updated computer system and the latest software applications to help students master the skills needed to create, modify, and analyze 2D and 3D designs. With the help of CAD software, students can design mechanical products and other structures with greater accuracy, efficiency, and speed.

The lab’s CAD software includes AutoCAD, SolidWorks, and among others. AutoCAD is a 2D drafting and 3D modeling software used by architects, engineers, and designers to create precise drawings and models. SolidWorks is a 3D CAD software used by mechanical engineers and product designers to create 3D models of products design and assemblies, another 3D CAD software used for product design and mechanical engineering.

Applied Thermodynamics Lab

The applied thermodynamics lab is an essential component of the mechanical engineering curriculum, which provides students with practical experience in conducting experiments related to thermodynamics. The experiments conducted in the lab enable students to apply the theoretical concepts learned in the classroom to real-world problems, and develop practical skills that are essential for their future careers.

Students learn about various types of low pressure and high pressure boiler, multi-cylinder engine test rig with facility to conduct the morse test, variable compression ratio engine, working models of engine components, model study for both SI and CI engines, ..etc.

Manufacturing Processes Lab

The manufacturing process lab is an important part of the engineering course. This lab aims to provide students with hands-on experience in the various stages involved in the manufacturing process.

The lab is equipped with machinery and tools, enabling students to gain practical experience in designing, prototyping, and manufacturing a wide range of products.

This lab’s curriculum focuses on imparting knowledge on the various manufacturing processes, including casting, forging, machining, and welding. Students learn how to design and manufacture products using different techniques and tools.

Heat Transfer Lab

Heat Transfer laboratory provides fundamental and industrial knowledge about modes of heat transfer, this labs aims to enhance knowledge of basic principles regarding heat transfer through three different methods: conduction, convection, and radiation.

Major equipments in this lab are heat exchangers of different types, Fin apparatus, Natural and Forced convection apparatus, emissivity measurement apparatus, and thermal conductivity measurement of insulating powders, etc.

From the data collected in each experiment, the students are able to observe the different ways of heat that can be transferred.

Python Lab

Python Programming Lab is an essential part of any computer science curriculum, and it plays a crucial role in the education of students studying in the field of programming. The lab helps students to learn and understand various programming concepts, syntax, and techniques using the Python programming language. This lab incorporates with Python programming into development process to ensure the creation of efficient, robust, and scalable web applications.

Refrigeration and Air Conditioning Lab

Refrigeration and Air Conditioning are critical components of modern society. These technologies allow us to cool buildings, preserve food and medicines, and provide comfortable environments for work and leisure. A Refrigeration and Air Conditioning Lab in Mechanical Engineering provides students with hands-on experience in the design, operation, and maintenance of refrigeration and air conditioning systems.

In the Refrigeration & Air Conditioning Lab, students learn the principles of vapour compression systems, vapour absorption system and practical applications.

The experiments performed in the lab help students understand the theoretical principles behind refrigeration and air conditioning and provide them with the practical skills required to design and build efficient systems.

Theory of Machine Lab

The Theory of Machine (TOM) is an important area of study in mechanical engineering. The goal of this lab is to introduce students to the fundamental concepts and principles of TOM and to give them experience of various mechanisms, kinematics, dynamics, and machine design.

This lab provides the facilities which make students gain immense knowledge about major equipments like universal vibration testing machine, static and dynamic balancing machine, cam and follower mechanism, working system of brakes, clutches, links and different mechanism, etc.

Measurement & Metrology Lab

The Measurement and Metrology lab is an integral part of any engineering curriculum. The lab is designed to impart knowledge on the principles and applications of instrumentation and measurement of surface finish, strain, temperature, pressure and flow in engineering.

The aim of the lab is to provide practical training to the students on the use of various measuring instruments and to develop their skills in measurement techniques and operation of Sine Bar, Slip Gauges, Bevel Protractor, Stroboscope, Dial Indicator, limits, fits & tolerances for selective assembly Vernier Caliper and Screw gauge, etc.

Polytechnic Program

Vision of the Department:

To provide outcome-based education to the students and fulfill the requirements of the industry as well as the society in the field of Mechanical Engineering.

Mission of the Department:

M-1: To provide a good environment for the student to grasp the knowledge of subjects/Courses.

M-2:To build a close Interaction of education with industries for improving the knowledge of the students for employability in the field of Mechanical Engineering.

M-3: To provide valuable and ethical knowledge classes for students.

M-4: To provide technical/vocational knowledge to the students to be an entrepreneur in the field of Mechanical Engineering.

Program Educational Objectives

(PEOs)

The Program Educational Objectives (PEO) is the program to prepare the Diploma holders for their career and professional living in Mechanical Engineering offered by Seth Vishambhar Nath Institute of Engineering and Technology, Barabanki, Uttar Pradesh, affiliated to Board of Technical Education, Uttar Pradesh INDIA are:

PEO-1: To be capable of applying technical knowledge, and skills of Mechanical Engineering in Industries.

PEO-2: To Inculcate the knowledge of communication skills, soft skills, entrepreneurship skills, and lifelong learning skills in the students

PEO-3 To encourage students to pursue higher education for better employment benefits.

Attributes / Program Outcomes (POs)

(Diploma in Engineering, students will be able to)

PO-1: Basic and Discipline specific knowledge: Apply knowledge of basic mathematics, science and engineering fundamentals and engineering specialization to solve the engineering problems.

PO-2: Problem analysis: Identify and analyze well-defined engineering problems using codified standard methods.

PO-3: Design/ development of solutions: Design solutions for well-defined technical problems and assist with the design of systems components or processes to meet specified needs.

PO-4: Engineering Tools, Experimentation and Testing: Apply modern engineering tools and appropriate technique to conduct standard tests and measurements.

PO-5: Engineering practices for society, sustainability and environment: Apply appropriate

technology in context of society, sustainability, environment and ethical practices.

PO-6: Project Management: Use engineering management principles individually, as a team member or a leader to manage projects and effectively communicate about well-defined engineering activities.

PO-7: Life-long learning: Ability to analyze individual needs and engage in updating in the context of technological changes.

Program-Specific Outcomes

(PSOs)

After the successful completion of the Diploma Program in “Mechanical Engineering,” the students will have

PSO-1 Quality & Maintenance Skill: Ability to manage the Quality of products and the maintenance of the systems.

PSO-2 Modern Tool & Software Usage: Ability to operate software-based modern tools for modeling the product.

PSO-3 Specific Knowledge & Higher Education: Ability to apply the fundamentals knowledge of Mechanical Engineering to solve Engineering problems and encourage them to higher education.

Syllabus